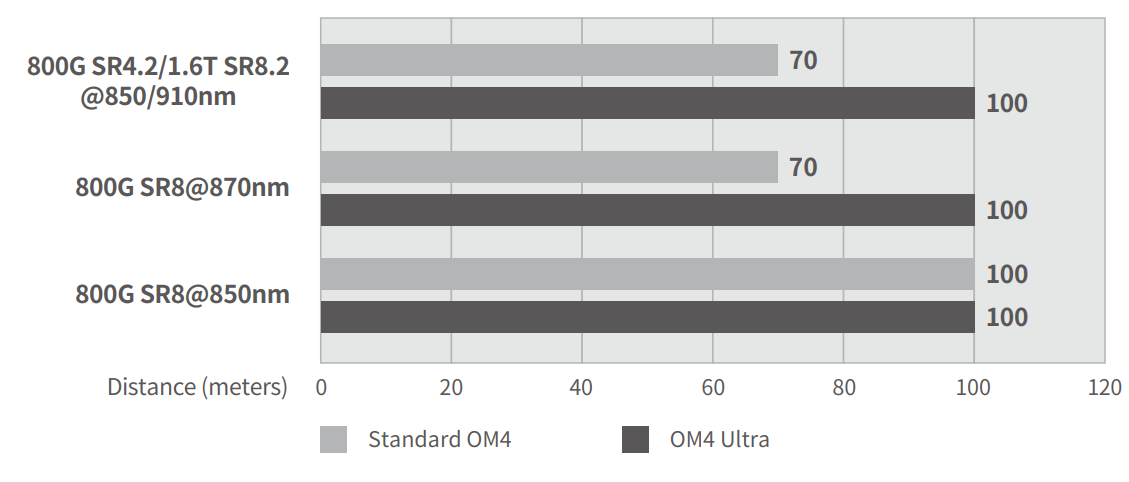

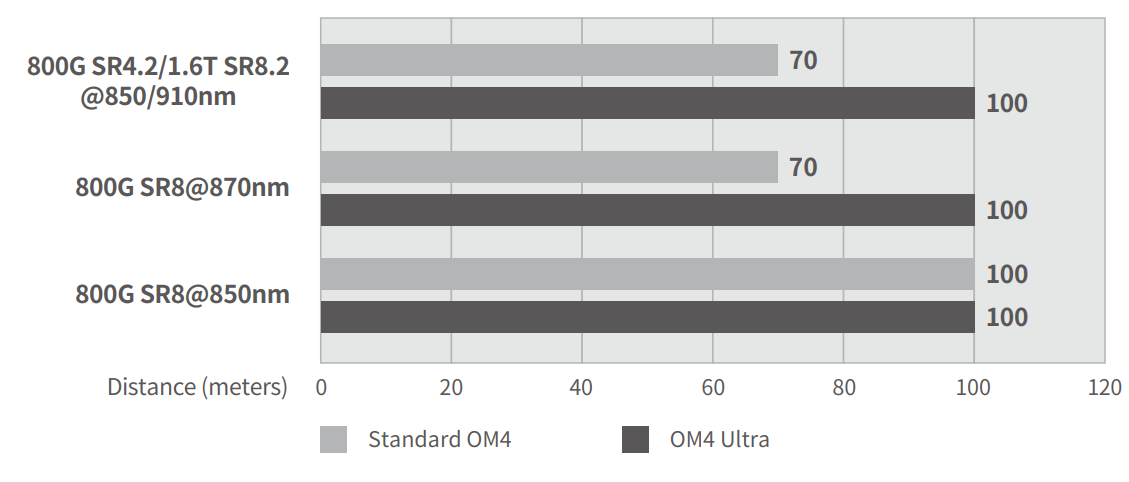

YOFC MaxBand® OM4 Ultra Bending Insensitive Multimode Fibre can support transmission distances of

100m in 100G/lane and Terabit BiDi links which complies with or exceeds IEEE 802.3db specification

and Terabit BiDi MSA specification.

YOFC MaxBand® OM4 Ultra Bending Insensitive Multimode Fibre is designed for 100G/lane and Terabit BiDi technology, offering high bandwidth in the wavelength range of 850nm - 870nm & 910nm. It can compensate the signal degradation caused by the center wavelength shift of 100G/lane transceivers, ensuring smooth upgrades to 400G, 800G, and higher data rates for data centers. It is fully backward compatible with legacy OM4 and OM5 fibres.

YOFC MaxBand® OM4 Ultra Bending Insensitive Multimode Fibre complies with or exceeds ISO/IEC 11801-1 OM4 specification, IEC 60793-2-10 A1-OM4 specification, and TIA-492AAAF A1-OM4 specification.

| Features | Benefits and Applications |

|---|---|

|

|

|

|

|

|

|

|

YOFC MaxBand® OM4 Ultra Bending Insensitive Multimode Fibre can support transmission distances of

100m in 100G/lane and Terabit BiDi links which complies with or exceeds IEEE 802.3db specification

and Terabit BiDi MSA specification.

| Characteristics | Conditions | Specified Values | Units | |

|---|---|---|---|---|

| Geometry Characteristics | ||||

| Core Diameter |

-- |

50±2.5 |

[μm] |

|

| Core Non-Circularity |

-- |

≤5.0 |

[%] |

|

| Cladding Diameter |

-- |

125.0±1.0 |

[μm] |

|

| Cladding Non-Circularity |

-- |

≤0.6 |

[%] |

|

| Coating Diameter |

-- |

245±7 |

[μm] |

|

| Coating/Cladding Concentricity Error |

-- |

≤10.0 |

[μm] |

|

| Coating Non-Circularity |

-- |

≤6.0 |

[%] |

|

| Core/Cladding Concentricity Error |

-- |

≤1.0 |

[μm] |

|

| Delivery Length |

-- |

up to 17.6 |

[km/reel] |

|

| Optical Characteristics | ||||

| Attenuation | 850nm |

≤2.4 |

[dB/km] |

|

|

910nm |

≤2.0 |

[dB/km] |

||

|

1300nm |

≤0.6 |

[dB/km] |

||

| Overfilled Modal Bandwidth |

850nm |

≥3500 |

[MHz·km] |

|

|

1300nm |

≥500 |

[MHz·km] |

||

| Effective Modal Bandwidth |

850nm-870nm |

≥4700 |

[MHz·km] |

|

|

910nm |

≥3100 |

[MHz·km] |

||

| Link Length |

800GBase-SR8 |

100 |

[m] |

|

| 800GBaseSR-4.2 | 100 | [m] | ||

| Numerical Aperture |

-- |

0.200±0.015 |

-- |

|

| Group Refractive Index |

850nm |

1.482 |

-- |

|

|

1300nm |

1.477 |

-- |

||

| Zero Dispersion Wavelength, λ0 |

-- |

1295-1340 |

[nm] |

|

| Zero Dispersion Slope,S0 |

1295nm≤λ0≤1310nm |

≤0.105 |

[ps/(nm2·km)] |

|

|

1310nm≤λ0≤1340nm |

≤0.000375(1590-λ0) |

[ps/(nm2·km)] |

||

| Macrobending Loss1 |

-- |

-- |

-- |

|

| 2 Turns @ 15 mm Radius |

850nm |

≤0.1 |

[dB] |

|

|

1300nm |

≤0.3 |

[dB] |

||

| 2 Turns @ 7.5 mm Radius |

850nm |

≤0.2 |

[dB] |

|

|

1300nm |

≤0.5 |

[dB] |

||

|

Backscatter Characteristics 1300nm |

||||

| Step(Mean of Bidirectional Measurement) |

-- |

≤0.10 |

[dB] |

|

| Irregularities Over Fibre Length and Point Discontinuity |

-- |

≤0.10 |

[dB] |

|

| Attenuation Uniformity |

-- |

≤0.08 |

[dB/km] |

|

|

Environmental Characteristics 850nm & 1300nm |

||||

| Temperature Cycling |

-60℃ to 85℃ |

≤0.10 |

[dB/km] |

|

| Temperature-Humidity Cycling |

-10℃ to 85℃ , 4% to 98% RH |

≤0.10 |

[dB/km] |

|

| Water Immersion |

23℃, 30 days |

≤0.10 |

[dB/km] |

|

| Dry Heat |

85℃,30 days |

≤0.10 |

[dB/km] |

|

|

Damp Heat |

85℃, 85% RH, 30 days |

≤0.10 |

[dB/km] |

|

| Mechanical Specification | ||||

| Proof Test |

-- |

≥9.0 |

[N] |

|

|

-- |

≥1.0 |

[%] |

||

|

-- |

≥100 |

[kpsi] |

||

| Coating Strip Force | typical average force |

1.5 |

[N] |

|

| peak force |

≥1.3,≤8.9 |

[N] |

||

|

Dynamic Stress Corrosion Susceptibility Paraeter(nd, typical) |

-- |

20 |

-- |

|

Remarks: 1. The launch condition for the macrobending loss measurement fulfils that described in IEC 61280-4-1.