• Distributed Temperature System

• Low attenuation at DTS operating wavelength 1450nm, 1550nm and 1650 nm

• High bandwidth at C-band (especially at 1550nm)

• High temperature resistance

• Low splicing loss

• Excellent bending insensitivity

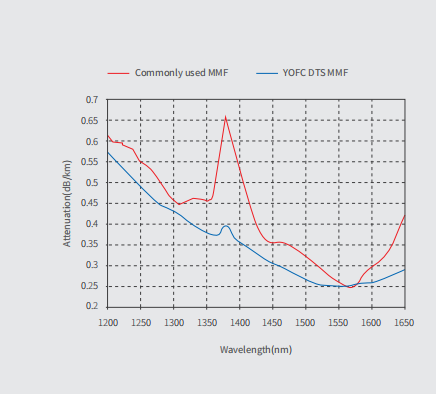

1.Low attenuation at DTS operating wavelength

The lower attenuation of the DTS-MMF at the wavelength of1450nm, 1550nm and 1650nm can increase the distance of the distributed temperature measurement system.

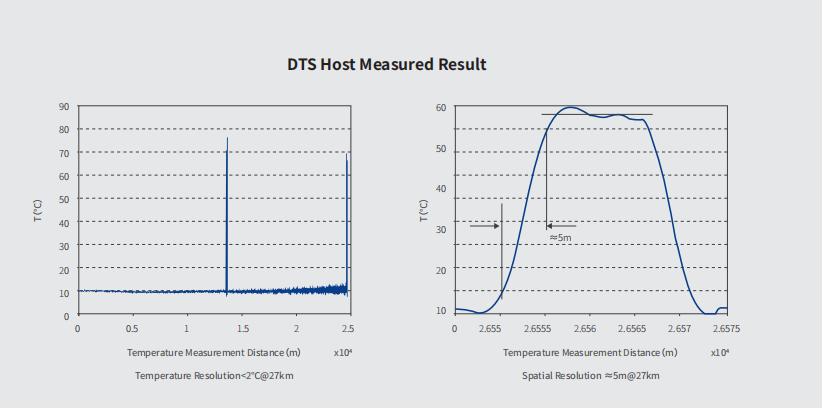

2.High bandwidth at 1550nm

According to IEC 60793-1-41-2010 (bandwidth), the actual measured bandwidth at 1550nm of DTS-MMF can exceed more than 1000MHz·km, which effectively improves the spatial resolution of the long-distance distributed temperature measurement system.

|

Fibre Type |

GI62.5/125-27/250DTS |

GI50/125-20/250DTS |

||

|---|---|---|---|---|

|

Part No. |

GI2015-B |

GI2012-B |

||

|

Optical Properties |

||||

|

Numerical Aperture (NA) |

0.275±0.02 |

0.195±0.02 |

||

|

Loss |

@1300(dB/km) |

≤0.6 |

≤0.5 |

|

|

@1450 nm(dB/km) |

≤0.5 |

≤0.45 |

||

|

@1550 nm(dB/km) |

≤0.4 |

≤0.28 |

||

|

@1650 nm(dB/km) |

≤0.5 |

≤0.45 |

||

|

Splicing Loss (dB) |

≤0.1 |

≤0.1 |

||

|

Bandwidth |

@1300 nm(MHz·km) |

≥200 |

≥200 |

|

|

@1550 nm(MHz·km) |

≥1000 |

≥1000 |

||

|

Geometrical Properties |

||||

|

Fibre Core Radium (μm) |

62.5±1.5 |

50±1.5 |

||

|

Cladding Diameter(μm) |

125±0.7 |

125±0.7 |

||

|

Fibre Diameter (μm) |

245±7 |

245±7 |

||

|

Concentricity of Core Cladding (μm) |

≤1.5 |

≤1.5 |

||

|

Non-circularity of Core (%) |

≤5.0 |

≤5.0 |

||

|

Non-circularity of Cladding (%) |

≤0.6 |

≤0.6 |

||

|

Macro Bending Attached Attenuation |

||||

| Macrobend Loss(dB) |

|

|

||

|

Two Circles Radius: 15mm |

1300 nm |

≤0.2 |

≤0.3 |

|

|

1550 nm |

≤0.2 |

≤0.3 |

||

|

Two Circles Radius: 7.5mm |

1300 nm |

≤0.3 |

≤0.5 |

|

|

1550 nm |

≤0.3 |

≤0.5 |

||

|

Mechanical Properties |

||||

|

Proof Test Level (kpsi) |

≥100 |

≥100 |

||

|

Environmental Properties |

||||

|

Operating Temperature Range(℃) |

-40~+85/-40~+150(Optional) |

-40~+85/-40~+150(Optional) |

||