- Protect bare fibre in any situation against mechanical damage during handling and installation

- Provide an effective resistance to water vapor, oils/fuels, acids/alkalis, and solvents, which could adversely affect the fibre's signal transmission capabilities

- Excellent wear properties in many applications, and in cases of high voltage, radiant, medical equipments

- Can be easily installed over fibre up to more than 5 meters

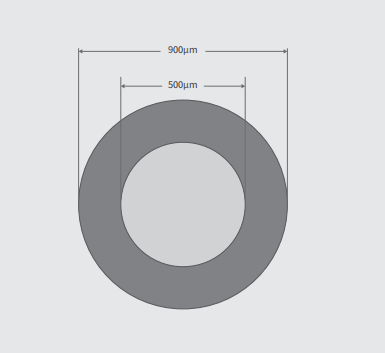

YOFC's 900 micron ETFE tubing can be employed as buffering material and provide additional protection for use with 250μm fibre.

Made from ETFE possessing, ETFE tubing has some excellent property of the material, such as resistance to heat and flame, and high specific dielectric strength, and gives optimal protection to 250μm fibre.

- Highest flame retardant grade of UL94 V-0

- Flexibility at low temperature

- Retention of properties after aging at elevated temperatures up to 150℃

|

Inner Diameter (μm) |

Outer Diameter (μm) |

Core Concentricity Error |

Non-Circularity |

|---|---|---|---|

|

500.0 ± 50.0 |

900.0 ± 50.0 |

< 6% |

< 3% |

|

Flame Retardant Grade |

UL94 V-0 & RoHS |

||

|---|---|---|---|

|

Tubing Shrinkage@85℃, 4 hours |

≤ 2.0% |

||

|

Material |

Property |

Value |

Test Method |

|

ETFE |

Flexural Modulus (MPa) |

641.1 |

ASTM D790 |

|

Tensile Strength at 23℃ (MPa) |

37.9 |

ASTM D1708 |

|

|

Elongation at 23℃ (%) |

> 300 |

ASTM D1708 |

|

|

Melt Point (℃) |

220 - 255 |

ASTM D3159 |

|

|

LOI |

34 |

ASTM D2863 |

|

|

Operating (℃) |

Static Diameter (mm) |

Storage (℃) |

Dynamic Diameter (mm) |

Installation (℃) |

|---|---|---|---|---|

|

-55 to +150 |

10 x Tight tube diameter |

-40 to +80 |

20 x Tight tube diameter |

-20 to +50 |

|

|

Blue |

BU |

|

Orange |

OR |

|

Green |

GN |

|

|

Brown |

BR |

|

Gray |

GY |

|

White |

WHT |

|

|

Red |

RD |

|

Black |

BK |

|

Yellow |

YW |

|

|

Violet |

VT |

|

Pink |

PN |

|

Light Blue |

LB |

- Customer colors are available through minimum order.

- Remark: YOFC can provide different diameter ETFE tight buffered fibre of various fibre, according to the requirement of client.