YOFC MaxBand® WideBand OM5 Bending Insensitive Multimode Fibre is a 50µm laseroptimized multimode fibre designed for short wavelength division multiplexing (SWDM) applications. Unlike legacy OM4 multimode fibre with high bandwidth at 850nm, YOFC MaxBand® OM5 Bending Insensitive Multimode Fibre has high bandwidth in the 850-950nm window and maintaining backward compatiblity with legacy OM4 fibre. WideBand OM5 and multi-wavelength transceivers are a viable solution for 100Gb/s and 400Gb/s multiwavelength systems.

YOFC MaxBand® WideBand OM5 Bending Insensitive Multimode Fibre complies with or exceeds ISO/IEC 11801-1 OM5 specification, IEC 60793-2-10 A1-OM5 specification, and TIA- 492AAAF A1-OM5 specification.

| Features | Benefits and Applications |

|---|---|

|

|

|

|

|

|

|

|

|

Characteristics |

Conditions |

Specified Values |

Units |

|

|---|---|---|---|---|

|

Geometry Characteristics |

||||

|

Core Diameter |

-- |

50±2.5 |

[μm] |

|

|

Core Non-Circularity |

-- |

≤5.0 |

[%] |

|

|

Cladding Diameter |

-- |

125.0±1.0 |

[μm] |

|

|

Cladding Non-Circularity |

-- |

≤0.6 |

[%] |

|

|

Coating Diameter |

-- |

245±7 |

[μm] |

|

|

Coating/Cladding Concentricity Error |

-- |

≤10.0 |

[μm] |

|

|

Coating Non-Circularity |

-- |

≤6.0 |

[%] |

|

|

Core/Cladding Concentricity Error |

-- |

≤1.0 |

[μm] |

|

|

Delivery Length |

-- |

up to 17.6 |

[km/reel] |

|

|

Optical Characteristics |

||||

|

Attenuation |

850nm |

≤2.4 |

[dB/km] |

|

|

953nm |

≤1.7 |

[dB/km] |

||

|

1300nm |

≤0.6 |

[dB/km] |

||

|

Overfilled Modal Bandwidth |

850nm |

≥3500 |

[MHz·km] |

|

|

953nm |

≥1850 |

[MHz·km] |

||

|

1300nm |

≥500 |

[MHz·km] |

||

|

Effective Modal Bandwidth |

850nm |

≥4700 |

[MHz·km] |

|

|

953nm |

≥2470 |

[MHz·km] |

||

|

Application support distance on |

-- |

-- |

-- |

|

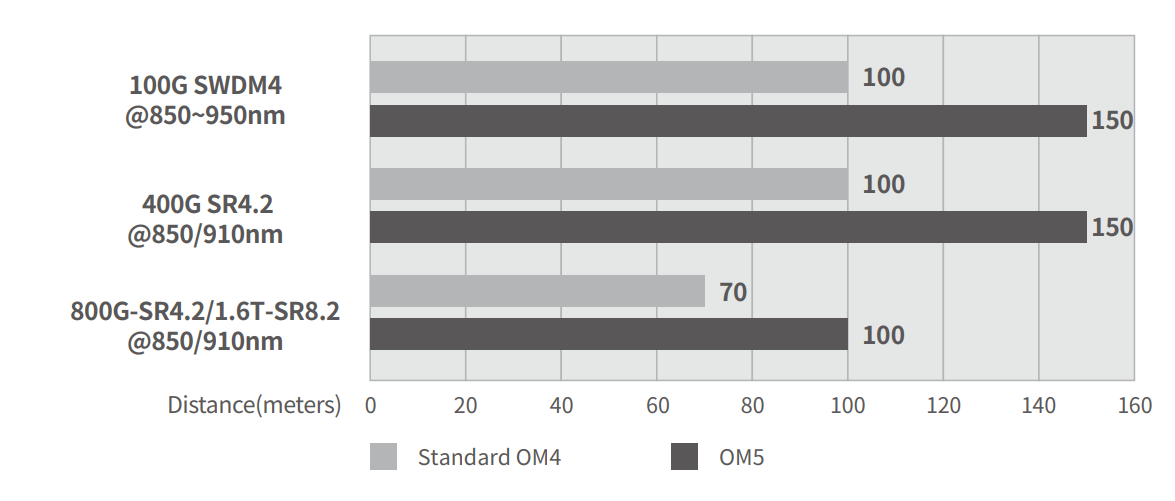

| 1.6T-SR8.2 | 850/910nm | 100 | ||

| 800G-SR4.2 | 850/910nm |

100 |

[m] |

|

| 400GBASE-SR4.2 | 850/910nm |

150 |

[m] |

|

| 100Gb/s WDM1 | 850-950nm |

150 |

[m] |

|

|

Numerical Aperture |

-- |

0.200±0.015 |

-- |

|

|

Group Refractive Index |

850nm |

1.482 |

-- |

|

|

1300nm |

1.477 |

-- |

||

|

Zero Dispersion Wavelength(λ0) |

-- |

1297-1328 |

[nm] |

|

|

Zero Dispersion Slope(S0) |

-- |

≤4(-103)/(840(λ0/840)4) |

[ps/(nm2·km)] |

|

|

Macrobending Loss2 |

-- |

@850nm |

@1300nm |

-- |

|

2 Turns @ 15 mm Radius |

-- |

≤0.1 |

≤0.3 |

[dB] |

|

2 Turns @ 7.5 mm Radius |

-- |

≤0.2 |

≤0.5 |

[dB] |

|

Backscatter Characteristics |

850nm & 1300nm | |||

|

Step(Mean of Bidirectional Measurement) |

-- |

≤0.10 |

[dB] |

|

|

Irregularities Over Fibre Length and Point Discontinuity |

-- |

≤0.10 |

[dB] |

|

|

Attenuation Uniformity |

-- |

≤0.08 |

[dB/km] |

|

|

Environmental Characteristics |

850nm & 1300nm | |||

|

Temperature Cycling |

at -60℃ to 85℃ |

≤0.10 |

[dB/km] |

|

|

Temperature-Humidity Cycling |

at -10℃ to 85℃ and 4% to 98% RH |

≤0.10 |

[dB/km] |

|

|

Water Immersion |

at 23℃ for 30 days |

≤0.10 |

[dB/km] |

|

|

Dry Heat |

at 85℃ for 30 days |

≤0.10 |

[dB/km] |

|

|

Damp Heat |

at 85℃ and 85% RH for 30 days |

≤0.10 |

[dB/km] |

|

|

Mechanical Specification |

||||

|

Proof Test |

-- |

≥9.0 |

[N] |

|

|

-- |

≥1.0 |

[%] |

||

|

-- |

≥100 |

[kpsi] |

||

|

Coating Strip Force |

typical average force |

1.5 |

[N] |

|

|

peak force |

≥1.3, ≤8.9 |

[N] |

||

|

Dynamic Stress Corrosion Susceptibility Parameter(nd, typical) |

-- |

20 |

-- |

|

Remarks: 1. Support distance with SWDM transceivers http://www.swdm.org/msa/

2. The launch condition for the macrobending loss measurement fulfils that described in IEC 61280-4-1.